bursting strength test standard|proof pressure vs burst : manufacture Standard Test Method for Bursting Strength of Textile Fabrics—Diaphragm Bursting Strength Tester Method. Significance and Use. 5.1 This method for the determination of . Resultado da 23 de fev. de 2023 · Instructions. Pour 8 cups of water into a large stock pot and add the chicken, the half onion (not diced), garlic, salt and pepper. Bring to a low boil and then .

{plog:ftitle_list}

Homens de Negro II - assistir online: streaming, compre ou alugue. Você pode assistir "Homens de Negro II" no HBO Max legalmente online, no .

rycobel burst strength chart

When determining the strength of a box, the corrugated box industry uses two test, the Bursting (Mullen) Strength Test and the Edge Crush Test (ECT). The Bursting Test is reported in pounds and is related to the handling durability of the box material. Standard Test Method for Bursting Strength of Textile Fabrics—Diaphragm Bursting Strength Tester Method. Significance and Use. 5.1 This method for the determination of .Smithers perform burst tests to BS 3137, BS 2922:1, ISO 2758 and ISO 2759. The burst test is frequently used as a general guide to the strength of paper, solid board and corrugated board. Bursting strength is usually quoted in kPa.

This International Standard specifies a method for measuring the bursting strength of paper submitted to increasing hydraulic pressure. It is applicable to paper having bursting strengths .

ASTM standards provide for several test methods for burst testing, including dynamic, static, creep, and creep to fail tests. These tests are used to measure the strength of medical device package sterile barrier systems as well as .

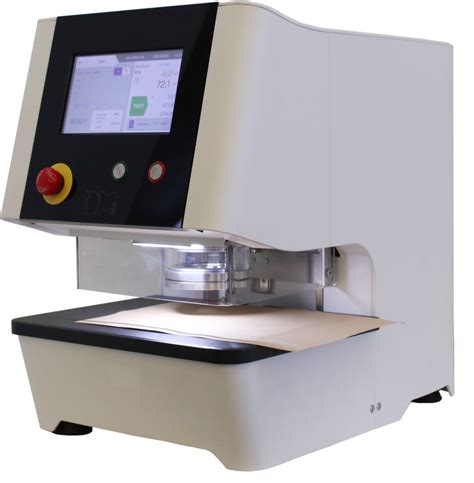

Pneumatic Bursting Strength Tester with TestWise™ software and a range of bursting strength and fatigue tests suitable for knitted textiles, medical textiles, nonwovens and plastics. In this installment of our Your Questions Answered .Burst testing, also known as burst strength testing or burst pressure testing, is a crucial evaluation technique used across industries to determine how much internal pressure a material can withstand before it ruptures or bursts.The ASTM D3786 Bursting Strength test method describes the measurement of the resistance of textile fabrics to bursting using a hydraulic or pneumatic diaphragm bursting tester.

This International Standard specifies a method for measuring the bursting strength of paper submitted to increasing hydraulic pressure. It is applicable to paper having bursting strengths .

We determine bursting strength using a digital hydraulic paper or digital hydraulic board burst tester as shown below. Burst index (kPa.m2/g) = burst strength/basis weight. Standards and accreditation. Smithers UKAS ISO . 5.2 In cases where test results obtained using the procedures in Test Method D3786 have not been correlated with actual performance, Test Method D3786 is considered satisfactory for acceptance testing of commercial shipments of textile fabrics for bursting strength since the method has been used extensively in the trade for acceptance testing. In .

AS/NZS 1301-403s:1997, Methods of test for pulp and paper — Bursting strength of paper. Appita standard 1 [5] TAPPI T 1200, Interlaboratory evaluation of test methods to determine TAPPI repeatability and reproducibility [6] Brauns O., Danielsson E., Jordansson L., Svensk Paperstidning 23 867 (1954) 1) [7]Our Digital Bursting Strength Tester complies with many bursting strength test standards, such as GB∕T7742.1-2005, ISO13938-1-2019, ASTM D3786/D3786M-18, etc. Enquiry. Description ; Reviews (15) Test Method ; FAQs ; . Significance of the bursting strength test of fabric. Tensile strength testing is less applicable to certain fabrics (e.g .The Autoburst gives unmatched performance in bursting strength and intelligence. The hydraulic system provides 6000 kPa (871 psi) of pressure to handle most any material. If you have heavy duty fabrics or need to comply with a test standard that specifies hydraulic testing, the Autoburst is the answer. STANDARD TEST HEAD SELECTION 30.5 mm (7.3 cm2) FedEx and UPS follow ISTA standards for packaging 30 pounds or less to be at least 32 ECT. 3 - Burst Test (Mullen Burst Test) The Mullen Test measures how much force is required to burst the main the force required to burst the corrugated board or paperboard.

ISO 2758:2014 specifies a method for measuring the bursting strength of paper submitted to increasing hydraulic pressure. It is applicable to paper having bursting strengths within the range 70 kPa to 1 400 kPa.determining the strength of a box, the corrugated box industry uses two test, the Bursting (Mullen) Strength Test and the Edge Crush Test (ECT). The Bursting Test is reported in pounds and is related to the handling durability of the box material. It is measured and determined by the force required to puncture or rupture the actual corrugated box.

proof pressure vs burst

The Mullen Test or Bursting Strength Test checks the toughness of the walls of the corrugated board when subjected to force or pressure. In this testing procedure, a rubber diaphragm is used to apply pressure to the walls of the corrugated box until it bursts. . There is the Sutherland Rub Test, which is an industry-standard testing procedure . Scope1.1 This test method covers measurements of the bursting strength of paper and paper products occurring as single or laminated flat sheets not over 0.6mm. (0.025 in.) in thickness having a bursting strength of 30 kPa up to 1400 kPa (4 psi up to 200 pThis test, also known as a Mullen Burst Test, is one of the most common material properties test required by carriers and governments. Bursting Strength testing basically measures the force required to puncture through a corrugated board. This strength comes from various factors, including the thickness of the paper liner layers, the narrowness of the flutes, and the layers of .The ISO 2759 Burst test specifies a method for measuring the bursting strength of board submitted to increasing hydraulic pressure. . should be tested by ISO 2758 and the remainder by this International Standard. Principle. A test piece, placed over a circular elastic diaphragm, is rigidly clamped at the periphery but free to bulge with the .

It is applicable to all types of board (including corrugated and solid fibreboard) having bursting strengths within the range 350 kPa to 5 500 kPa. It is also applicable to papers or boards having bursting strengths as low as 250 kPa if the paper or board is to be used to prepare a material of higher bursting strength, such as corrugated board.

Test Standards: ASTM D 3786-01, ASTM D 3786 – 80A, ISO 1060 PART-1 1987. Available models: Bursting strength tester Analogue, Bursting strength tester Pneumatic model, Bursting strength tester computerized model with thermal printer connectivity . Testronix Instruments is a leading manufacturer and supplier of Bursting Strength Testers in India.SNAP-ON INCORPORATED Page 4 of 9 PRODUCT STANDARDS 3. Edgewise Compressive Strength (ECT for edge crush test) - relates more to the compressive strength of the box during stacking and is expressed in the amount of force per unit width (lbs-force/inch) when tested in accordance with ISO Standard 3037, FEFCO TM 8, TAPPI T 811, or CN GB/T 6546.Using the ‘push to burst’ switch to apply the hydraulic pressure on the sample. The pressure is applied via a rubber diaphragm which inflates when hydraulic pressure is increased. The point at which sample burst, the machine notes down the pressure applied. Using this bursting strength, bursting factor and bursting index can be determined.Determination of bursting strength This International Standard specifies a method for measuring the bursting strength ofboard submitted to increasing hydraulic pressure. It is applicable to all types of board (including corrugated and solid fibreboard) having bursting strengths Within the range 350 kPa to 5 500 kPa. It is also applicable to

While bursting strength is an empirical property, this test, in combination with grammage (basis weight), serves to define some “standard grades” in commerce. The bursting strength relates to sidewall puncture of the finished combined board and has been shown to be important in mixed load LTL types of shipments. See TAPPI T 810 for testing . Understanding Bursting Strength Test Standard. The bursting strength test standard is a crucial parameter in the packaging industry, as it measures the ability of a material to withstand pressure .

How Do You Test Bursting Strength According to the Standard? To perform a burst test according to the ASME PCC-2 guidelines, there are several straightforward steps to follow. These steps are important because they help ensure the safety and effectiveness of materials and products used in various applications.IS 1966 (Part 1): 2009 ISO 13938-1 :1999 6.1.2 Bursting pressure shall be indicated with an accuracy of ±2 % of full scale range above the first 20 % of range. 6.1.3 Height at burst up to 70 mm shall be indicated with an accuracy of ±1 mm. Zero position of the measuring gauge shall be adjustable to accommodate the thickness of the test specimen. Some of the most widely recognized bursting strength testing standards include: ASTM D3786 – Standard Test Method for Bursting Strength of Textile Fabrics**: This ASTM International standard specifies the procedure for determining the bursting strength of woven or knitted fabrics using a hydraulic bursting tester.

Performing the Bursting Strength Test/Mullen test. Performing the bursting strength is very easy and it can be easily conducted with the help of a very precise and accurate testing machine called bursting strength tester. It is important to keep in mind that while performing the bursting strength test, all the quality testing standards must be .

Standard Operating Procedure (SOP) for operation, calibration, and maintenance of Bursting Strength Tester used to analyze the packing material of drug products. SOP for Bursting Strength Tester 1.0 PURPOSE: The purpose of this SOP is to describe the operation, calibration, and maintenance of the Bursting strength tester. 2.0 SCOPE:

The influence of the test environment. In the top bursting strength test, the test environment has a great influence on the top bursting strength of the fabric, so the tester needs to strictly follow the standard to choose the corresponding test environment. Influence of the operator. The influence of testers’ readings.Table 3-13 Relevant domestic and international standards for testing the bursting strength of textiles. Standard: Name of Standard: Note: GB/T 7742—2005: Textiles-Determination of swelling strength and swelling expansion length-Elastic .Bursting strength is measured utilizing a rubber diaphragm that is expanded hydraulically against the paper sample. A bursting test is also known as a Mullen test [New Window] or pop test [New Window], and a minimum bursting strength is required for cartons used for shipping. Bursting strength has little application for printing papers.“ The .

WEBThere's an issue and the page could not be loaded. Reload page. 2M Followers, 3,714 Following, 2,591 Posts - See Instagram photos and videos from Nyvi Estephan .

bursting strength test standard|proof pressure vs burst